WAGO

For more than 60 years, WAGO has developed and produced innovative products for packaging, transportation, process, industrial and building automation markets amongst others. Aside from its innovations in spring pressure connection technology, WAGO has introduced numerous innovations that have revolutionized industry. Further ground-breaking inventions include: the WAGO-I/O-SYSTEM®, TOPJOB S® and WALL-NUTS®.

Power Your Appliances with WAGO Terminal Blocks

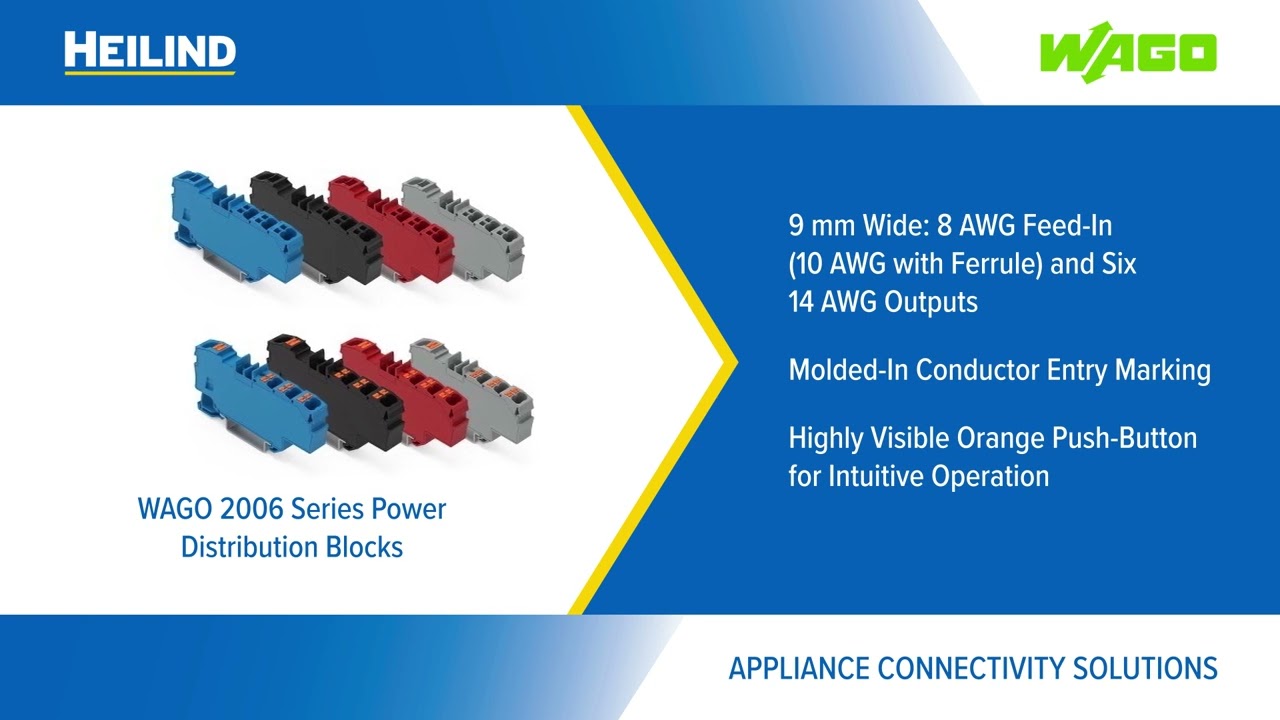

For reliable and efficient power distribution in appliances and HVAC systems, trust WAGO’s power distribution terminal blocks. Engineered for optimal performance and ease of use, our terminal blocks ensure secure and robust connections, making them the ideal choice for your electrical needs.

For reliable and efficient power distribution in appliances and HVAC systems, trust WAGO’s power distribution terminal blocks. Engineered for optimal performance and ease of use, our terminal blocks ensure secure and robust connections, making them the ideal choice for your electrical needs.

Featured products include:

Illuminate with Precision: WAGO Lighting Solutions

Transform your lighting, sign, and display projects with WAGO’s 207 series gel box and 221 series compact splicing connectors. Our solutions ensure reliable and secure connections, allowing your creations to shine brightly and beautifully. Choose WAGO for unmatched performance.

Transform your lighting, sign, and display projects with WAGO’s 207 series gel box and 221 series compact splicing connectors. Our solutions ensure reliable and secure connections, allowing your creations to shine brightly and beautifully. Choose WAGO for unmatched performance.

Featured products include:

Super-compact, tool-free PCB terminal block that allows for quick and easy wiring for cross-sections from 26 to 14 AWG.

Super-compact, tool-free PCB terminal block that allows for quick and easy wiring for cross-sections from 26 to 14 AWG.

These solid conductors and fine-stranded conductors with ferrules feature WAGO’s push-in CAGE CLAMP® connection technology that connects by simply pushing them into the unit. Terminating fine-stranded conductors and disconnecting any conductor type is quick and easy with the lever connection.

The trend toward ever more compact components also presents new challenges for power electronics. The increased power density brought about by combining the signal and output layer on the PCB also impacts connection systems. PCB terminal blocks must be compact so as to reliably transmit currents while, at the same time, also operating dependably together with the PCB under demanding conditions.

The trend toward ever more compact components also presents new challenges for power electronics. The increased power density brought about by combining the signal and output layer on the PCB also impacts connection systems. PCB terminal blocks must be compact so as to reliably transmit currents while, at the same time, also operating dependably together with the PCB under demanding conditions.

The new PCB terminal block line-up for power electronics combines all of these benefits: The terminal blocks are designed in 3 sizes to accept max wires sizes of 10, 8, and 4 AWG, with UL ratings up to 85A / 1000V. Options include a tool-operated version, or the version with levers for 100% tool-free termination.

Flexible, Fast and Safe!

Flexible, Fast and Safe!

WAGO’s 221 series compact splicing connectors are designed to easily terminate conductors in 2-, 3-and 5-wire configurations. Pull the lever up, insert a conductor and push the lever back down – done! The 221 Series Splicing Connector connects solid, stranded and fine-stranded conductors easily, quickly and safely.

The new connector family is 40% smaller than its predecessor – providing 40% more junction box space for the user. The housing is 100% transparent, allowing you to easily verify that the wire is inserted properly, and that the wire is stripped to a proper length.

Intuitive operation through highly visible orange push-button.

Intuitive operation through highly visible orange push-button.

Triple-deck push button terminal blocks feature the same industry-proven CAGE CLAMP® connection technology used throughout the TOPJOB S Series, known for its reliability and maintenance-free experience.

Solid, stranded (seven strands or less) or ferruled conductors can be terminated simply by pushing in the wire or utilizing the easy-to-identify, orange push-buttons using any standard tool. WAGO’s triple-deck blocks offer incredible space-savings within the control panel and with TOPJOB S jumpering system, a variety of jumper types can be utilized to satisfy any applications commoning needs.

The SMD 2065 Series PCB Terminal Block combines the smallest dimensions with high connection capacity, ideal for LED modules and other industrial applications. The compact design of the 2065 blocks, at just 2.7mm high, makes it an optimal PCB connection solution in any space-constrained application. These terminal blocks feature Push-in CAGE CLAMP® technology, which means that solid or tinned conductors may be terminated by pushing them into the block’s aperture. The push-in termination technology provides a reliable and repeatable alternative to wire soldering.

The SMD 2065 Series PCB Terminal Block combines the smallest dimensions with high connection capacity, ideal for LED modules and other industrial applications. The compact design of the 2065 blocks, at just 2.7mm high, makes it an optimal PCB connection solution in any space-constrained application. These terminal blocks feature Push-in CAGE CLAMP® technology, which means that solid or tinned conductors may be terminated by pushing them into the block’s aperture. The push-in termination technology provides a reliable and repeatable alternative to wire soldering.

The 2065 series also provide for convenient termination/removal of fine-stranded conductors via push-button and operating tool. The tool depresses the push-button to open the spring, while its funneled conductor opening securely guides the stranded conductor into the terminal block.

The 2065, which has no insulating housing, is intended for use in applications operating at a Safety Extra Low Voltage (SELV), or for connections inside enclosures in which protection against contact with high voltages is provided by the end product.

WAGO’s 2060 series features a very low profile (4.5mm total height); contoured edges; and a light color, all of which are aimed at reducing shadowing in LED applications.

WAGO’s 2060 series features a very low profile (4.5mm total height); contoured edges; and a light color, all of which are aimed at reducing shadowing in LED applications.

The 2060 Series offers superior conductor retention, and the highest electrical ratings (9A / 250V, plus 600V rating for single pole variant) of any connector in its class. It accepts the broadest range of wire sizes and types (18-24 AWG, solid, stranded, flexible, prepared), and the wire entry face features a “balcony” to provide convenient lead-in for wiring from a slight angle.

WAGO 857 Series relay and optocoupler modules are supplied in 6 mm-wide housing and share a common profile. The modules feature a single, flexible in-line jumper system (e.g., for supply voltages), eliminating discrete wiring. The pluggable relays can be replaced quickly and easily when needed.

WAGO 857 Series relay and optocoupler modules are supplied in 6 mm-wide housing and share a common profile. The modules feature a single, flexible in-line jumper system (e.g., for supply voltages), eliminating discrete wiring. The pluggable relays can be replaced quickly and easily when needed.

An optional interface adapter plugs on the input or output side, combining eight modules and connecting them via a flat cable.

Features/Benefits:

- Pluggable relays and optocouplers

- Industry‘s most compact – just 6.0 mm wide

- Potential commoning on every level

- Integrated LED for status indication

- Input voltage available in 5-230 V AC/DC variants

- Up to 8 A switching current

WHITE PAPER: 5 Reasons the 2065 Connector is a Reliable Alternative to Manual Soldering

Due to today’s increasingly automated age, there have been innovations in wave and reflow techniques that are technically sound for certain types of components, but the manual process of soldering yet remains when it comes to connecting flying leads, i.e. wires, to printed circuit boards. When done properly, it is a tried and true connection method that has endured. In this paper, we will explore the challenges encountered when hand soldering, and the WAGO alternative – the 2065 Series Surface Mount PCB terminal block including:

Due to today’s increasingly automated age, there have been innovations in wave and reflow techniques that are technically sound for certain types of components, but the manual process of soldering yet remains when it comes to connecting flying leads, i.e. wires, to printed circuit boards. When done properly, it is a tried and true connection method that has endured. In this paper, we will explore the challenges encountered when hand soldering, and the WAGO alternative – the 2065 Series Surface Mount PCB terminal block including:

- Hand soldering is not repeatable

- Soldering is hot and it can get that way quickly

- Cold solder joints are unseen dangers

- Too much solder is suboptimal

- Too little solder is suboptimal

Even though installers have for many years successfully used hand soldering techniques to connect wires to PCB component boards, as our industry moves beyond the age of artisan craftsmanship, WAGO’s 2065 Series Surface Mount PCB terminal blocks offer a risk-mitigating alternative. By eliminating variability in installation, they are easy to use, compact, safe, clean, temperature-cycling resistant, reusable and reliable over the lifetime of the end product.