Amphenol Aerospace MIL-DTL-38999 Connectors

For Military, Aerospace and Harsh Environments

Heilind Electronics is an authorized distributor for Amphenol Aerospace, which manufactures the largest selection of MIL-DTL-38999 connectors in the world. Fully QPL’d, these robust subminiature connectors are designed to meet the most stringent requirements of the military and aerospace industry.

Our Amphenol Aerospace MIL-DTL-38999 line includes Series I, II, and III, as well as a wide range of tailored and derivative products. We offer value-added assembly on all of our MIL-DTL-38999 connectors.

We also offer Amphenol Aerospace MIL-DTL-38999 Series I, II & III connectors with PC tail contacts. These high-density PCB connectors are lightweight, compact, and environmentally resistant. Series III is available with clinch nuts for fast and secure mounting.

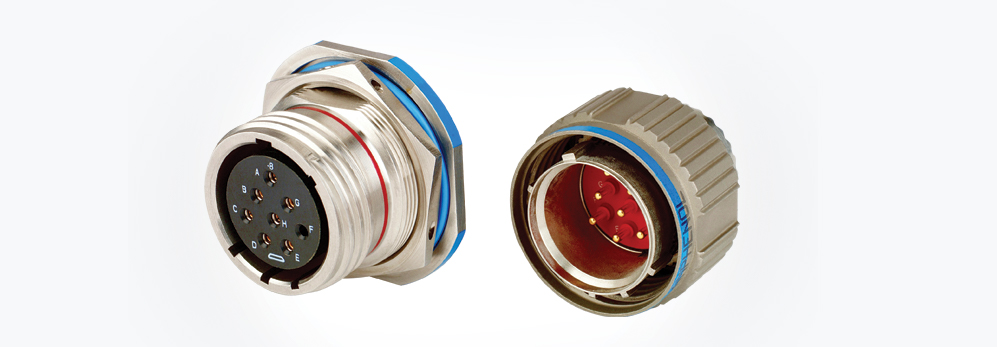

MIL-DTL-38999 Series I - LJT Connectors

Amphenol® MIL-DTL-38999 Series I Connectors were developed to meet the needs of the aerospace industry and provided the impetus for the development of the MIL-C-38999 specifications, which later was superseded by MIL-DTL-38999. Amphenol’s MIL-DTL-38999 Series I and commercial LJT series connectors meet or exceed the Mil-Spec requirements and are available in aluminum or stainless steel as well as several different finish options.

Part Prefix: MS27*, LJT*, JT

Key Features & Benefits:

- Lightweight, Space Saving Design

- Contact Protection – 100% scoop-proof design prevents bent pins and short circuits during mating

- Quick Positive Coupling – 3 point bayonet lock system

- Mismating Eliminated – with 5 key/keyway design

- Error Proof Alternate Positioning – insured by different key/ keyway locations

- EMI Shielding – grounding fingers standard

- Nine Shell Sizes and a Variety of Shell Styles

- Contact Options – size 8, 10, 12, 16, 20, 22M and 22D Crimp, Solder, PCB, Wire wrap, Coax, Twinax, Triax, Thermocouple, Fiber Optic and Filter

- Fixed Solder Contacts – Amphenol MIL-DTL-38999 Series I LJT are available in solder versions as both Commercial and Military qualified to MIL-DTL-27599

- “Breakaway” Lanyard Release Style – available in LJT plugs. Provides quick disconnect of the connector plug and receptacle with axial pull on the lanyard.

- Inventory Support Commonality – uses standard MIL-DTL-38999 contacts, insert arrangements and application tools.

- RoHS Compliant Product Available – Consult Amphenol Aerospace Operations.

MIL-DTL-38999 Series II - JT Connectors

Amphenol® MIL-DTL-38999 Series II Connectors were developed to meet the needs of the aerospace industry and provided the impetus for the development of the MIL-C-38999 specifications, which later was superseded by MIL-DTL-38999. Amphenol’s MIL-DTL-38999 Series II and commercial JT series connectors meet or exceed the Mil-Spec requirements and are available in aluminum or stainless steel as well as several different finish options.

Key Features & Benefits:

- Lightweight, Space Saving Design

- Quick Positive Coupling – 3 point bayonet lock system

- Mismating Eliminated – with 5 key/keyway design

- Error Proof Alternate Positioning – insured by different key/ keyway locations

- EMI Shielding – grounding fingers optional

- Nine Shell Sizes and a Variety of Shell Styles

- Contact Options – size 8, 10, 12, 16, 20, 22M and 22D Crimp, Solder, PCB, Wire wrap, Coax, Twinax, Triax, Thermocouple, Fiber Optic and Filter

- Fixed Solder Contacts – available in solder versions as both Commercial and Military qualified to MIL-DTL-27599

- Inventory Support Commonality – uses standard MIL-DTL-38999 contacts, insert arrangements and application tools.

- RoHS Compliant Product Available – Consult Amphenol Aerospace Operations.

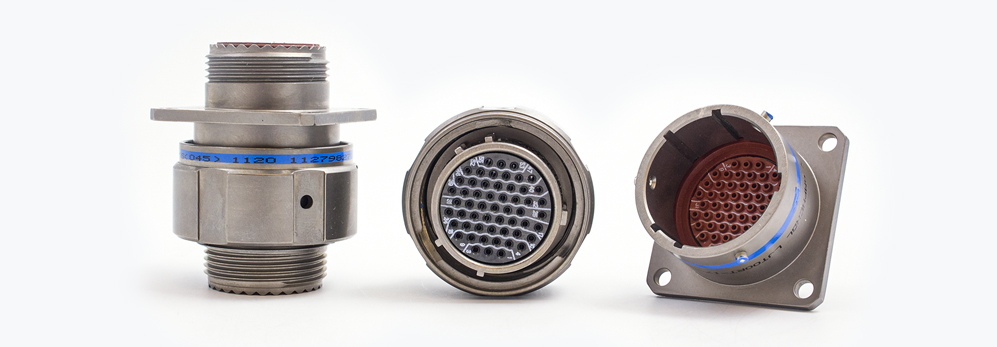

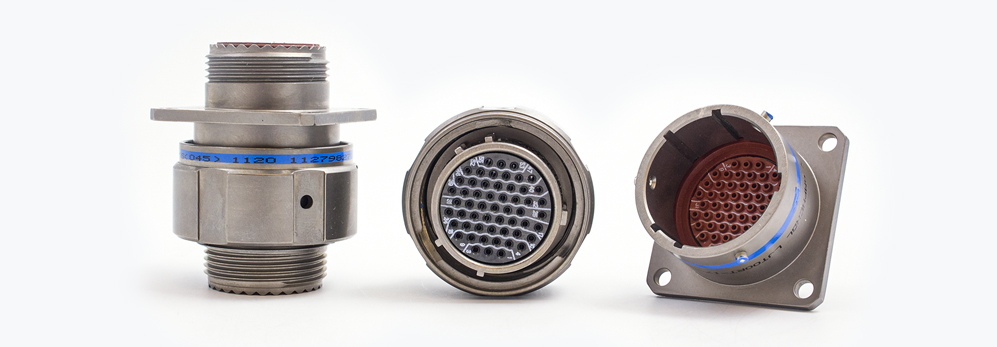

Tri-Start MIL-DTL-38999 Series III - TV Connectors

Amphenol® Tri-Start MIL-DTL-38999 Series III Connectors offer the highest performance capabilities for both general duty and severe environment applications. Meeting or exceeding MIL-DTL-38999 Series III requirements, Amphenol’s Tri-Start connector is available in aluminum, stainless steel or composite with several finish options.

Plating options include cadmium olive drab, zinc cobalt, electroless nickel, and RoHS-compliant black zinc nickel

Part Prefix: D38999*, TV*, CT*, MTV*

Key Features & Benefits:

- Aluminum, Stainless Steel, and Composite shells

- EMI Shielding: solid metal-to-metal coupling, grounding fingers provide superior EMI shielding

- 100% scoop-proof connector minimizes potential contact damage – Improved interfacial seal design

- Stainless steel or cadmium over nickel plating withstand a 500-hour salt spray exposure

- Operates under severe high-temperature vibration, through 392 °F (200 °C)

- Firewall Capability

- Unique, self-locking, quick coupling connector eliminates lockwiring

- Stainless Steel qualified to BACC63DB and BACC63DC specifications

MIL-DTL-38999 Class G Space Grade Connectors

Heilind now has the capability to value-add outgassed connectors for Amphenol D38999 series III.

Heilind now has the capability to value-add outgassed connectors for Amphenol D38999 series III.

These connectors are “space grade” as they are baked in a high temperature, high vacuum oven to remove potentially harmful substances before being launched into space. These connectors meet NASA and military specifications.

Applications:

- LEO Satellites

- Manned/Unmanned Space Vehicles

- Robotics

- Launch Systems

- Mission Control

Part identification and lead time:

- Military part numbers – D38999/*G, otherwise known as “G Class”

- Commercial part numbers beginning LJT, JT, or TV ending with a suffix of “453” or “467”

- Lead time for stock to build connectors is 15 days